Progressive by tradition

At STULZ, we have evolved from an innovative family business into a modern global player. Throughout this process, our history has been an important part of our DNA - customer focus, entrepreneurial spirit and technological expertise have made STULZ a pioneer in precision cooling and humidity control technology. With over 50 years of experience - in the cooling of mission-critical applications, in particular - we are the perfect partner by your side. We offer you not only processional consulting and air conditioning technology at the very highest level, but also customized service and a strong global partner.

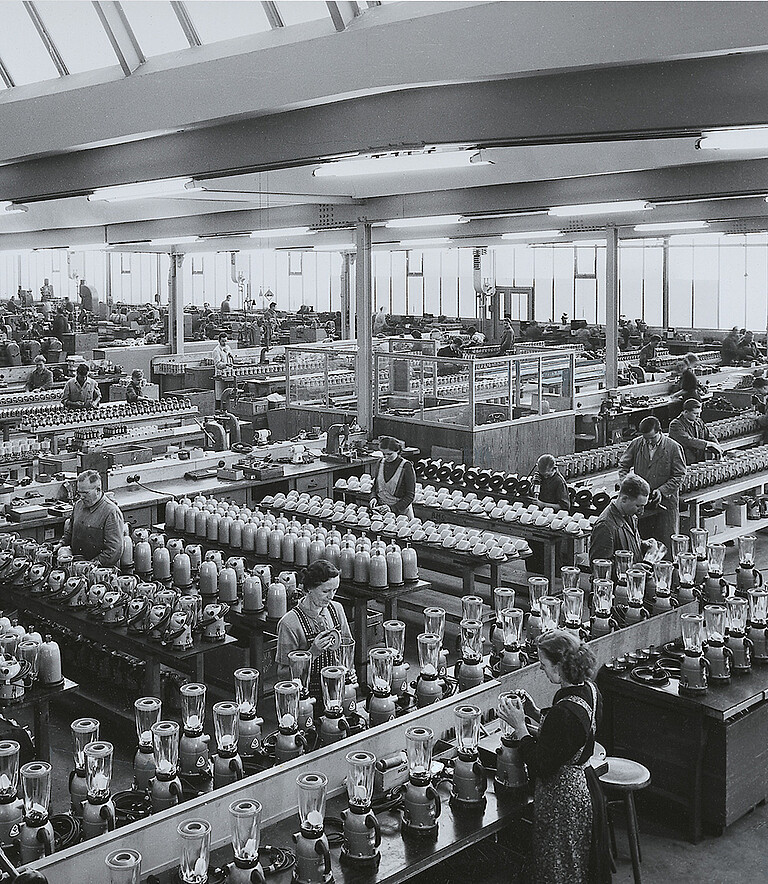

The early years

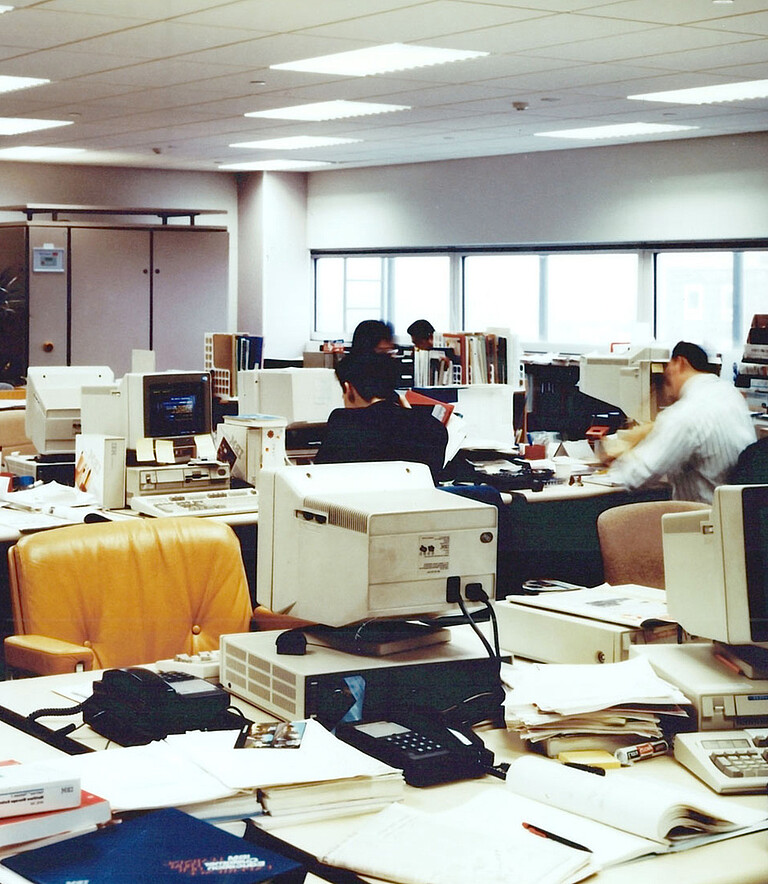

Boom in the IT sector

Continuous developments

Our future and our mission